Source: Pexels

As we enter a new decade of innovation, the inventory management landscape is ripe for significant transformation since the convergence of advancing technologies, shifting consumer demands, and global economic dynamics will no doubt herald a future where businesses must adapt swiftly to stay competitive.

Let’s explore six pivotal upcoming trends guaranteed to reshape everything you thought you knew about inventory management, change operational strategies, and draw a new line in the industry.

Sustainability-driven Inventory Optimization

Making your inventory eco-friendlier isn’t just good for the planet – it’s also smart business. Today, sustainability is far from being mere hype. In reality, it steers the ship for business strategies everywhere you look, and managing stock is now a balancing act that involves optimizing usage while trimming down waste and being kinder to our environment.

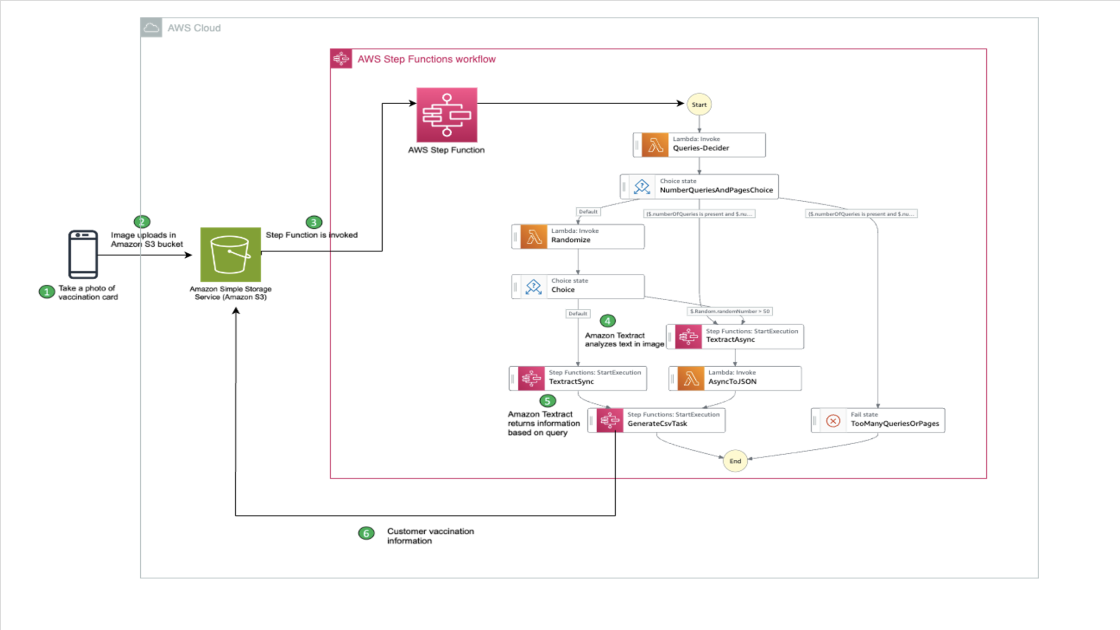

Imagine being able to intuit what you’ll need before you do – that’s what cutting-edge firms now do with AI-driven forecasts and instant monitoring systems that make inventory management effective.

When businesses match their inventory with what people buy, they cut down on unnecessary stock and make a smaller dent in the environment by reducing overproduction and shipping.

Enhanced Customer Satisfaction through Predictive Analytics

Imagine knowing what your customers want before they do. That’s the magic of predictive analytics for better, all-round satisfaction. Keeping your shelves stocked just right has become an art form, and predictive analytics is leading the charge in this customer-first era.

By digging into what folks have bought before, spotting seasonal patterns, and even checking out the buzz on social media, businesses are getting good at using data to know what people will want next and making sure top picks are a shelf staple while dialing back on slow-moving inventory. If you are curious about the bottom line, it’s seeing customers smile more, shelves stay full, and ever-growing brand loyalty.

Automation and Robotics Revolutionize Warehousing

Picture a world where robots handle all the heavy lifting in warehouses. Well, you don’t need to imagine because it’s happening now!

With help from robotic systems that can select items on their own and self-operating forklifts, stocking shelves and sending packages has never been smoother or faster.

One notable trend is the shift towards decentralized, technology-enabled warehouse setups. Imagine getting your orders quicker than ever because companies have smartly placed their nimble, automated storage spots near downtown areas.

This move slashes wait times and transport fees and creates a win-win situation! Spreading things out instead of relying on one main spot is empowering businesses and helping them dodge supply disruptions, nature’s curveballs, and other business challenges.

Blockchain Integration for Transparent Supply Chains

In an ever-interconnected global economy, supply chain transparency is paramount. With blockchain technology stepping into the spotlight, tracking goods from start to finish is now a breeze.

With the blockchain recording every deal in the supply chain on a ledger that never forgets or forgives, it’s now easier to offer top-notch transparency and foster rock-solid trust with extra security layers.

With the blockchain in play, tracing the roots of any product or verifying its authenticity has never been easier for companies. It’s like x-raying your entire supply chain process, thus keeping your business on good terms with those ever-so-strict regulators.

Embrace of Just-in-Time Inventory Practices

The traditional inventory management model will continue giving way to more agile and responsive approaches in an era characterized by rapid technological advancements and ever-changing consumer demands.

Thanks to lean manufacturing, keeping inventory just in time (JIT) is something a lot more industries are starting to get into, and businesses that know when to make stuff when people want it find themselves saving big on warehousing fees.

Adopting JIT inventory now could be your best bet at not only surviving but thriving by making operations smoother than ever before while eyeing bigger profit margins as we step further into this new era.

Personalized Inventory Management Solutions

As consumer preferences become increasingly diverse, more than one-size-fits-all inventory management solutions are needed. That’s perhaps why the industry is turning toward personalized inventory management solutions tailored to each business’s unique needs.

Whether it’s a small e-commerce startup or a multinational conglomerate, businesses can now leverage emerging modular inventory management platforms and trends that scale and adapt to their evolving requirements.

Step-by-step control over buying stuff, keeping track of it in storage, sharing it out, and topping up when necessary? Yes, please! That is where custom-fit answers let businesses sharpen their routines without sweat.

Final Thoughts

As we step forward, there’s one guarantee in inventory management: change never takes a day off. Embracing this fact is your ticket to leading the pack in the future.